画像 yield strength on stress strain curve 820180-Shear yield strength stress strain curve

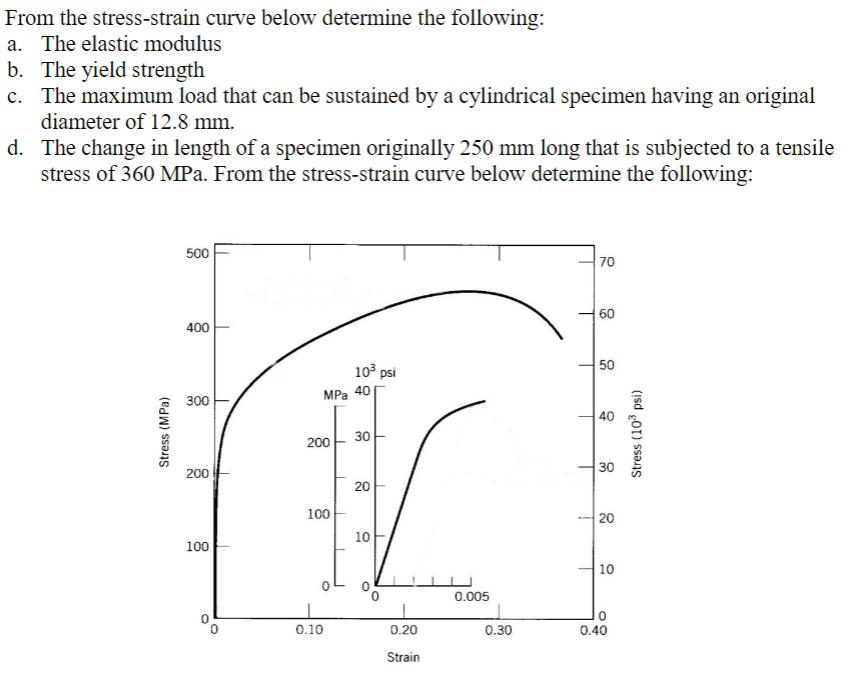

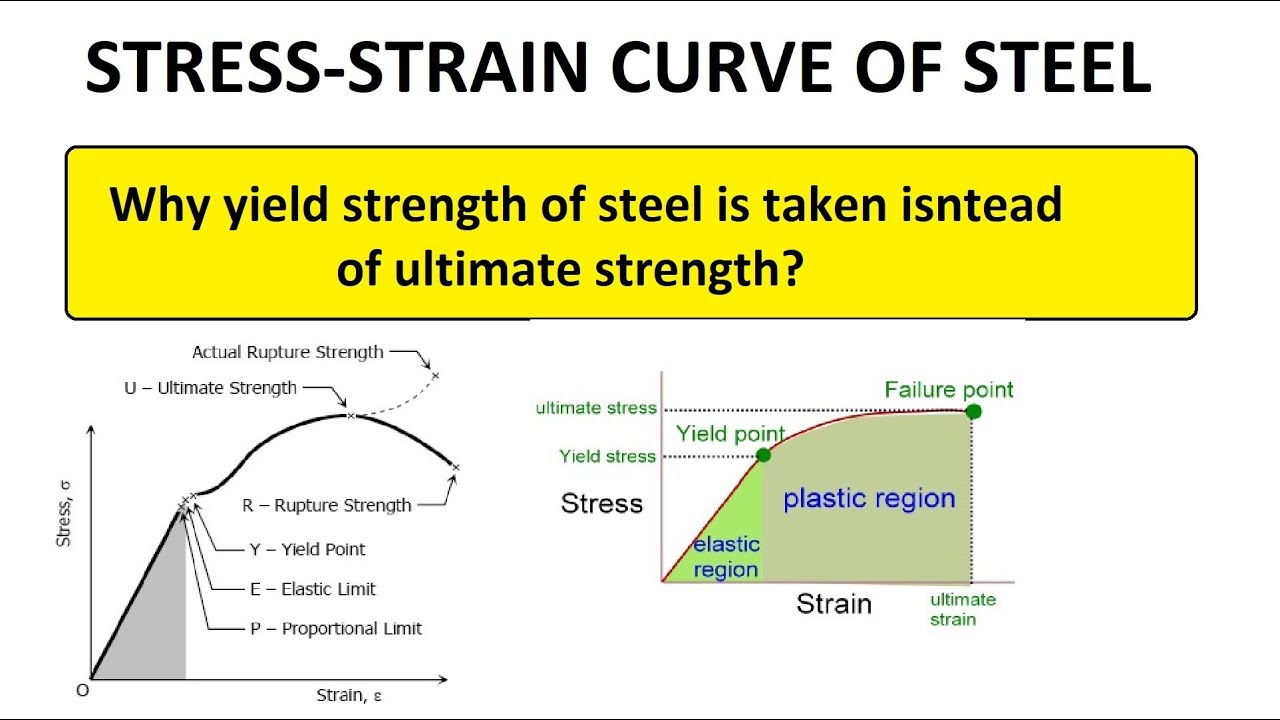

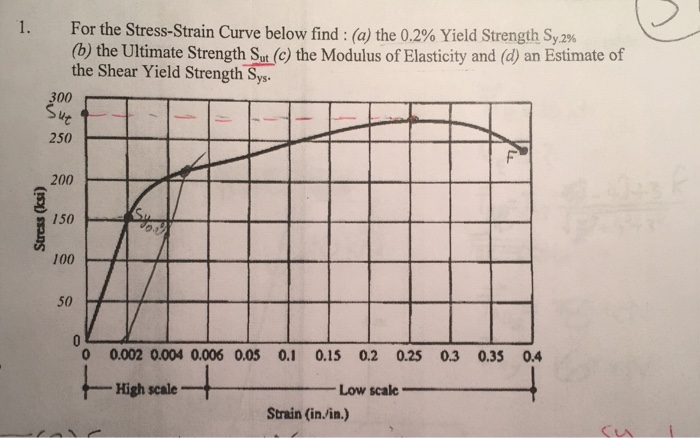

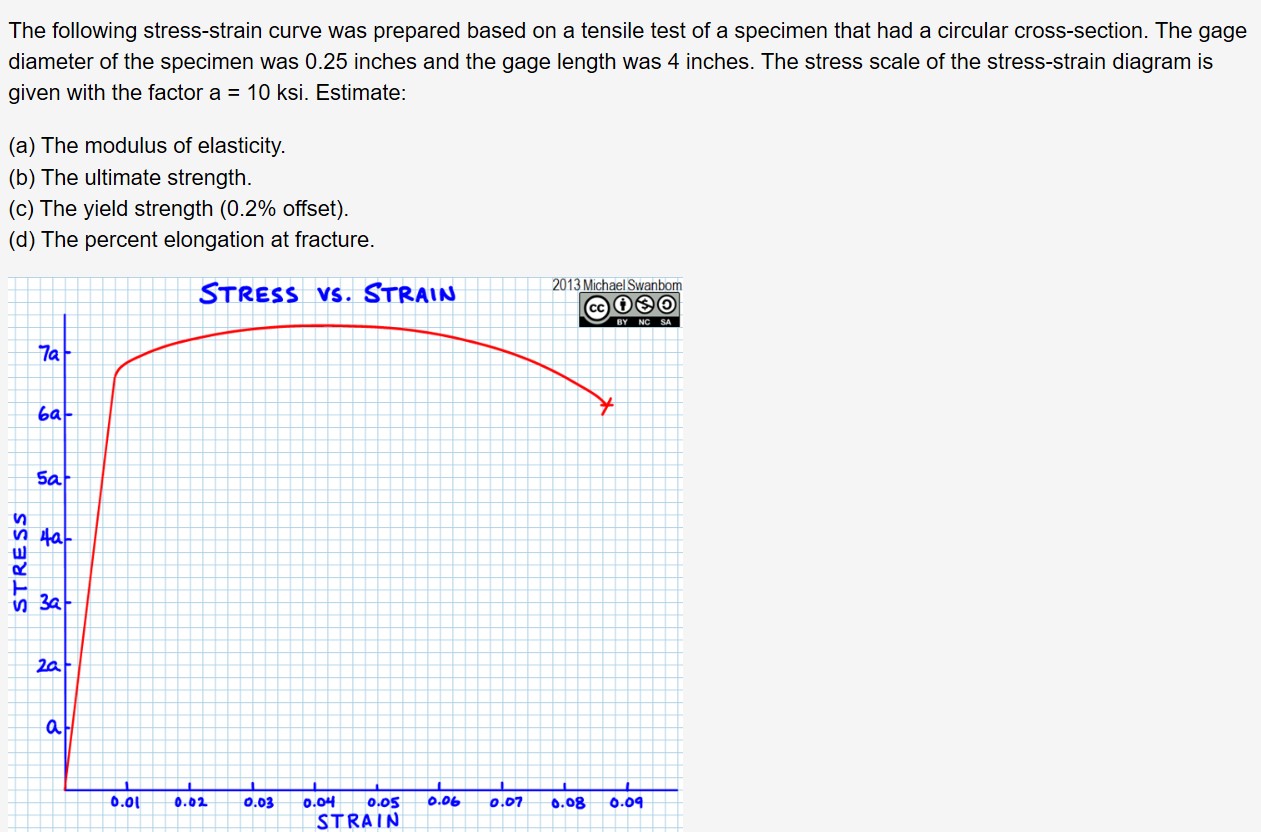

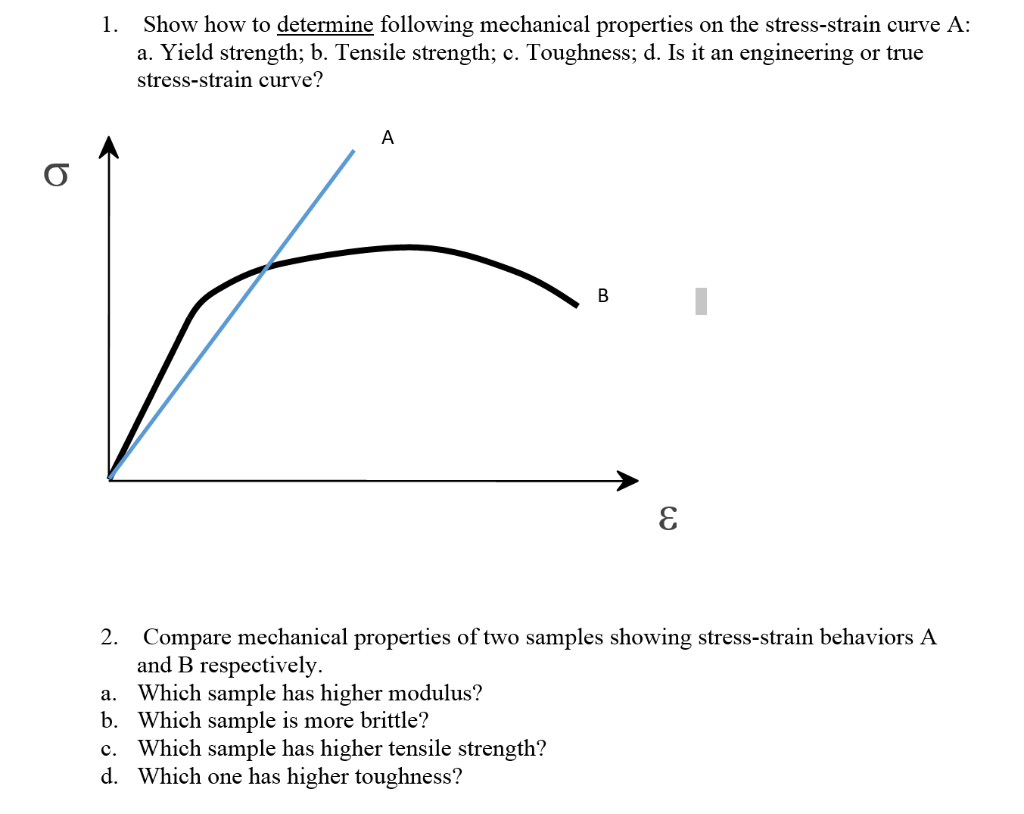

Question Please Draw Stressstrain Curve In Excel And Find Yield Strength,yield Strain, Stiffness,ultimate Strength,Resilience,Toughness,Brittleness,Ductility In (EL%) Original Length=006m Original Diameter= 15mm STRESS (N/mm2) STRAIN 0 0YP ⇒ Yield Point Stress at which there are large increases in strain with little or no increase in stress Among common structural materials, only steel exhibits this type of response σ YS ⇒ Yield Strength The maximum stress that can be applied without exceeding a specified value of permanent strain (typically 2% = 002 in/in)Question Please Draw Stressstrain Curve In Excel And Find Yield Strength,yield Strain, Stiffness,ultimate Strength,Resilience,Toughness,Brittleness,Ductility In (EL%) Original Length=006m Original Diameter= 15mm STRESS (N/mm2) STRAIN 0 0

Strength At Break Tensile

Shear yield strength stress strain curve

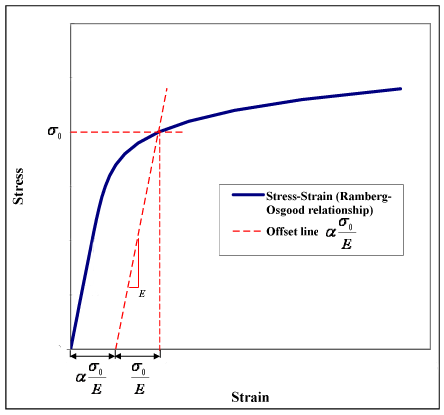

Shear yield strength stress strain curve-The stressstrain curve is approximated using the RambergOsgood equation, which calculates theYield Strength Definition Stress Strain Graph Stress Strain Graph Explanation Yield Strength Graph What is Yield Strength?

Nondestructive Evaluation Physics Materials

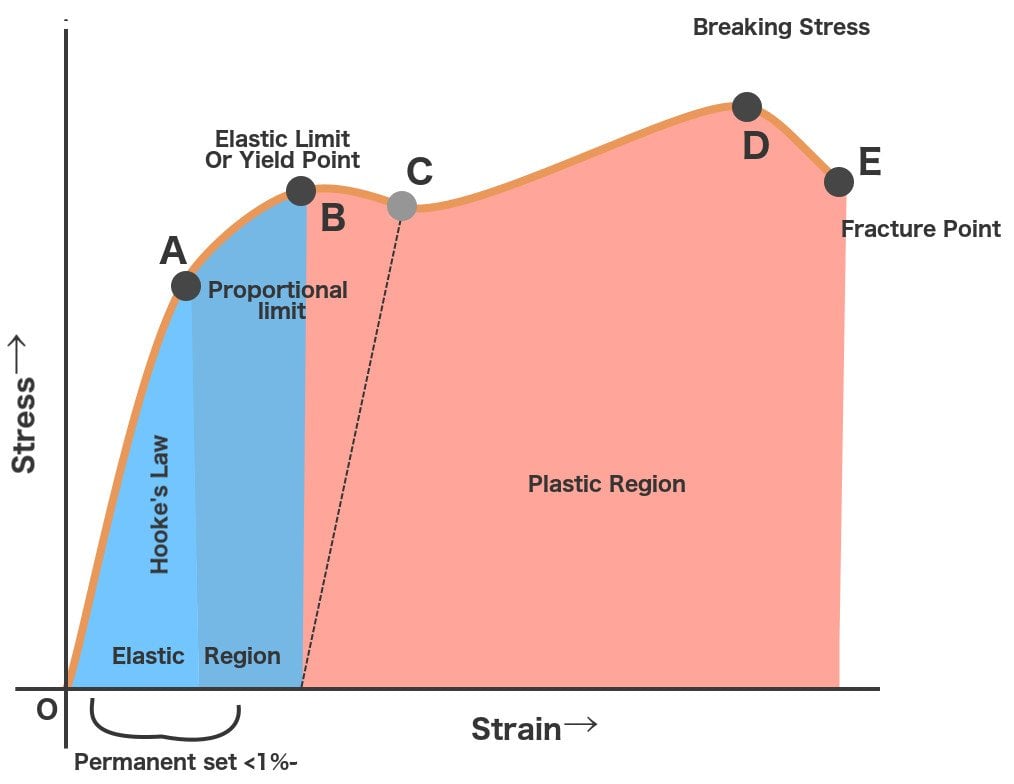

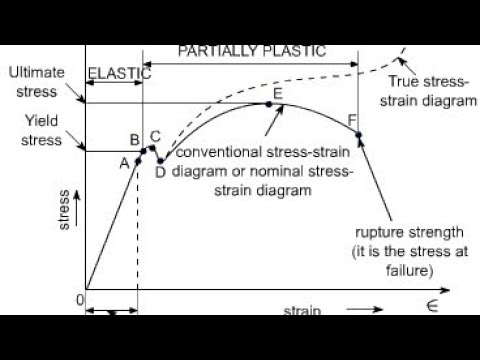

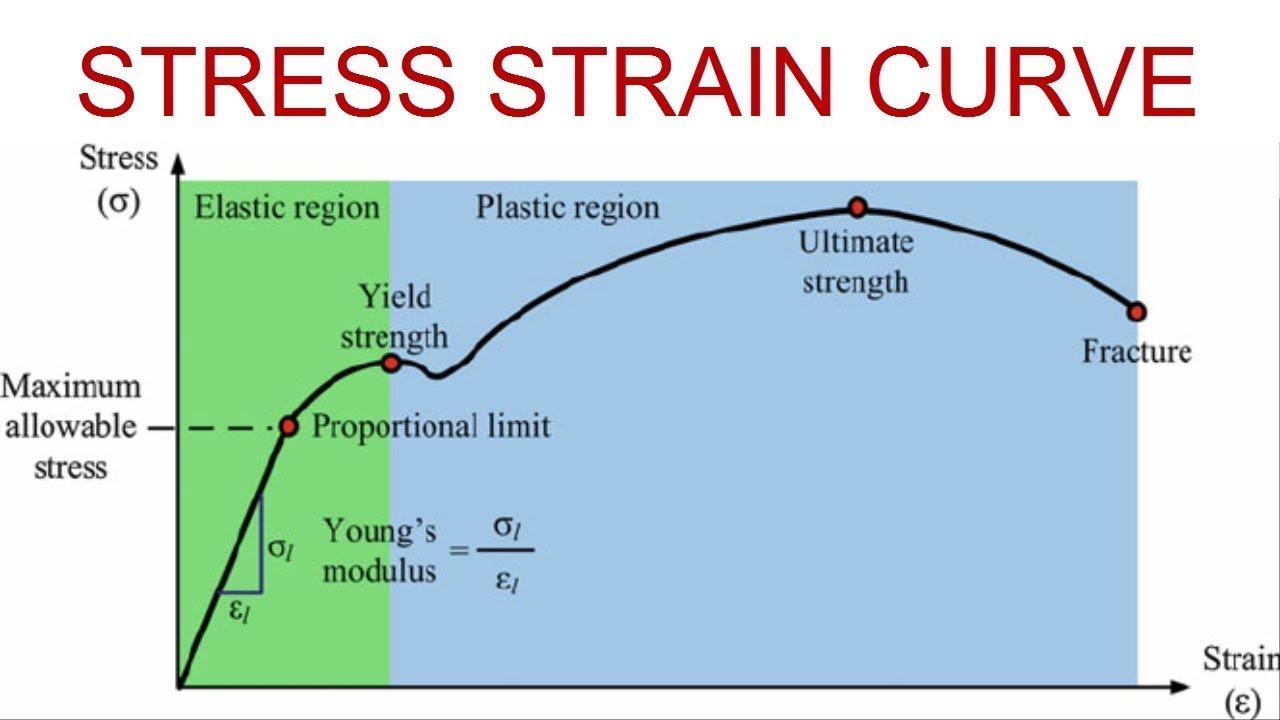

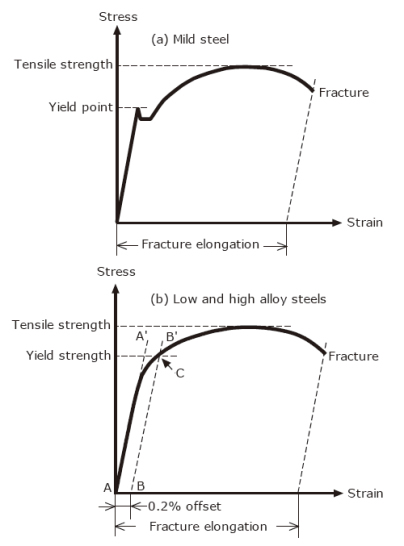

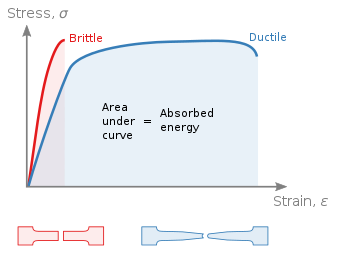

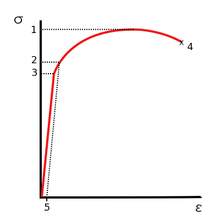

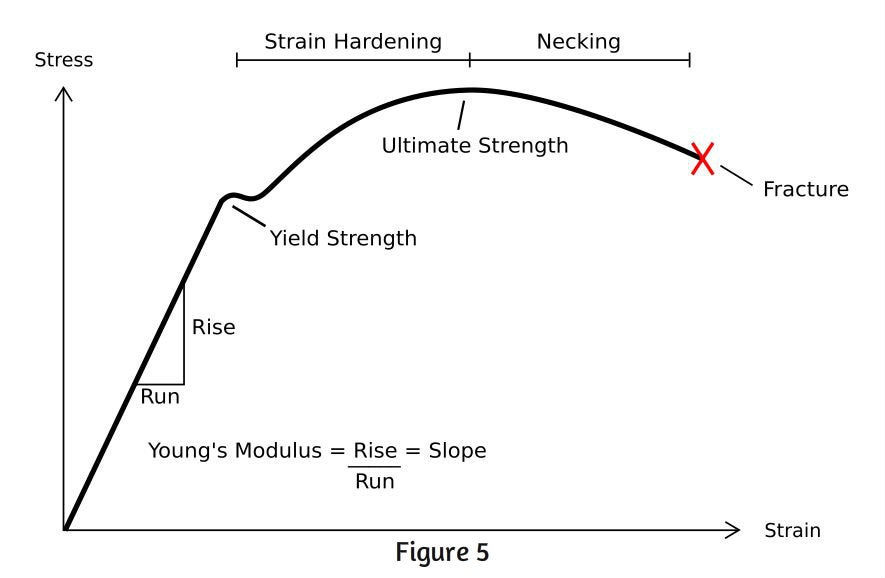

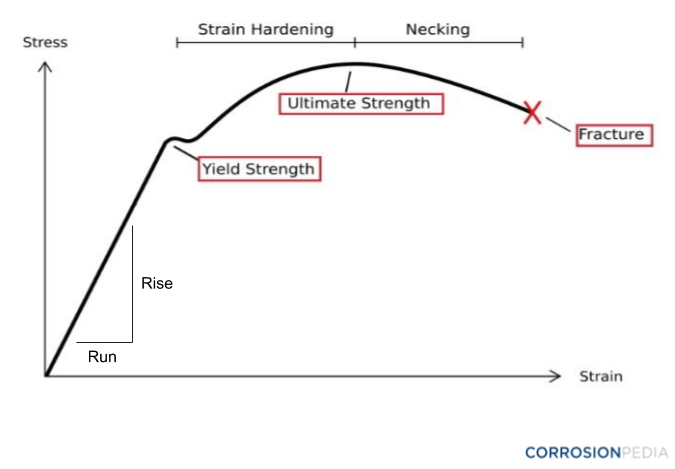

These curves reveal many of properties of materials, such as the Young's modulus, the yield strength, the ultimate tensile strength and so on Stress/Strain graph of a tension test experiment Stressstrain curve for material is plotted by elongating the sample and recording the stress variation with strain until the sample fracturesLet's understand the meaning of "Yield" first Yield point tells us a very interesting story about the failure of a structure or material In our highschool, we have read about Hooke's law It says that stress is proportional to strain up to a ceMore explicitly, a flow stress can be

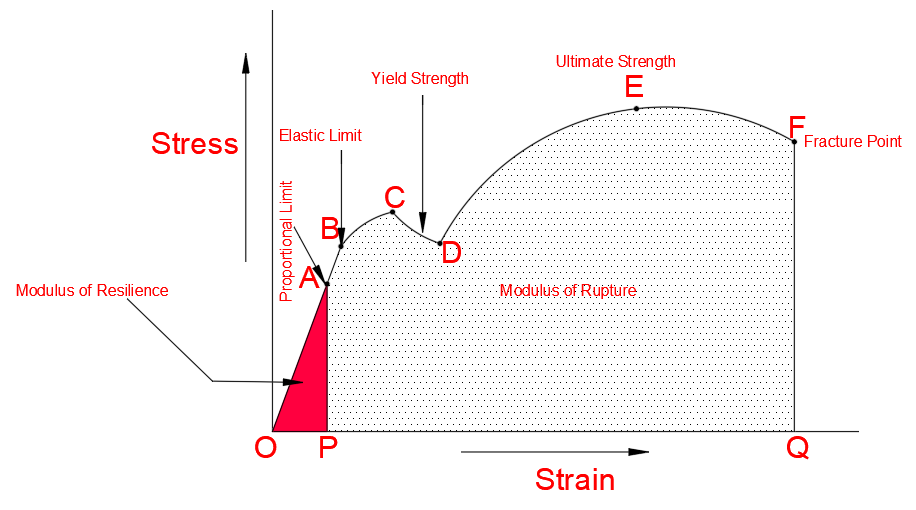

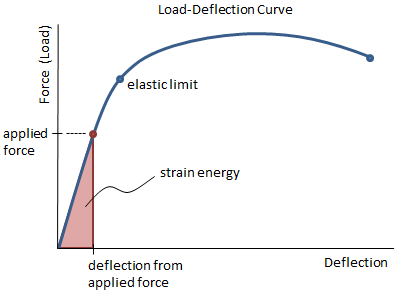

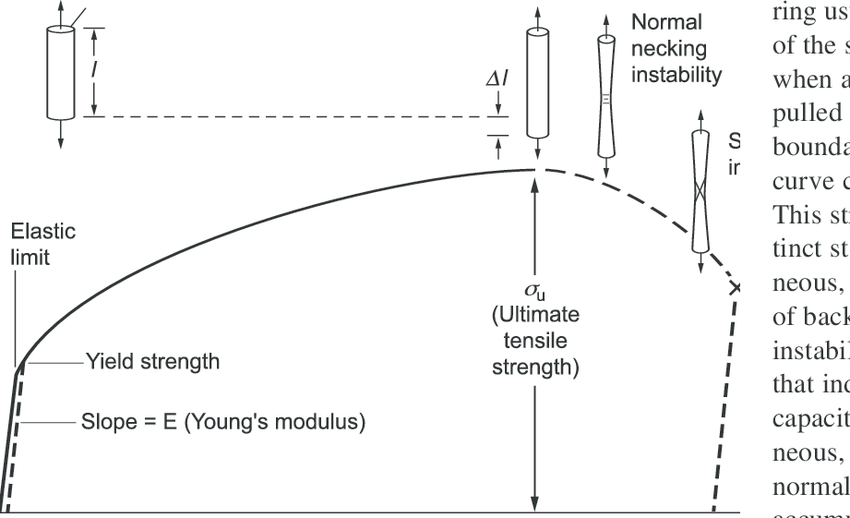

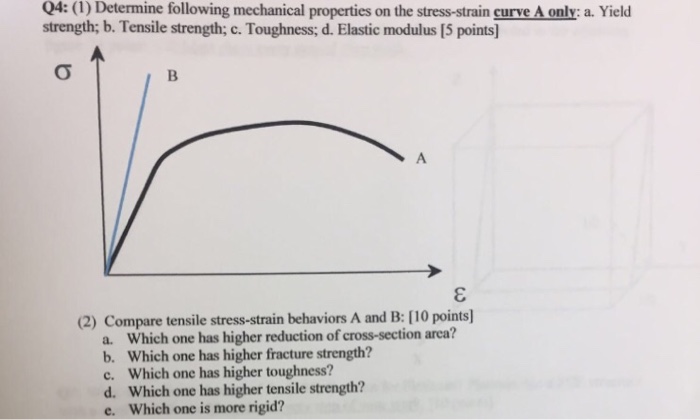

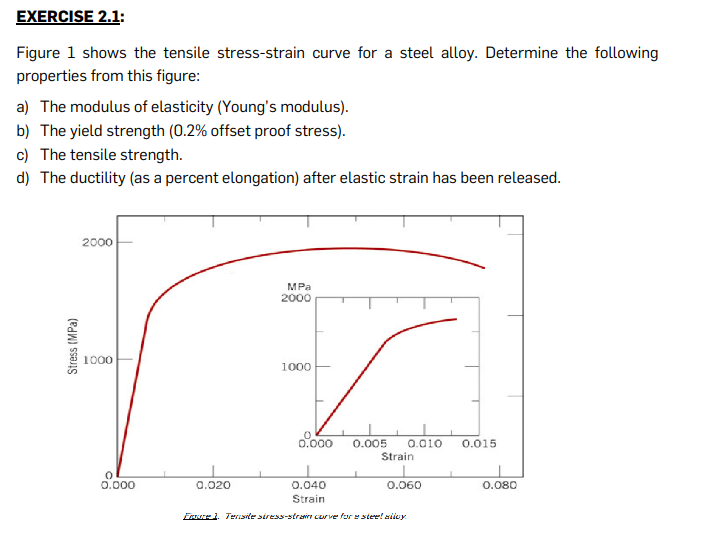

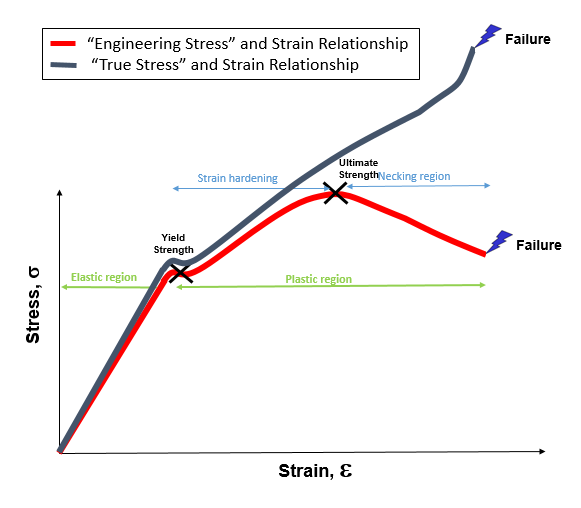

Both tensile strength and hardness are indicators of a metal's resistance to plastic deformation The stressstrain curve (Figure 1) above is a good way of graphically demonstrating this The ratio of stress to strain is the elastic modulus—stiffness, but the stress, and only the stress, defines the strength of the materialThe ultimate tensile strength is the maximum on the engineering stressstrain curve This corresponds to the maximum stress that can be sustained by a structure in tension Ultimate tensile strength is often shortened to "tensile strength" or even to "the ultimate" If this stress is applied and maintained, fracture will resultStress strain curve is the plot of stress and strain of a material or metal on the graph In this, the stress is plotted on the yaxis and its corresponding strain on the xaxis After plotting the stress and its corresponding strain on the graph, we get a curve, and this curve is called stress strain curve or stress strain diagram

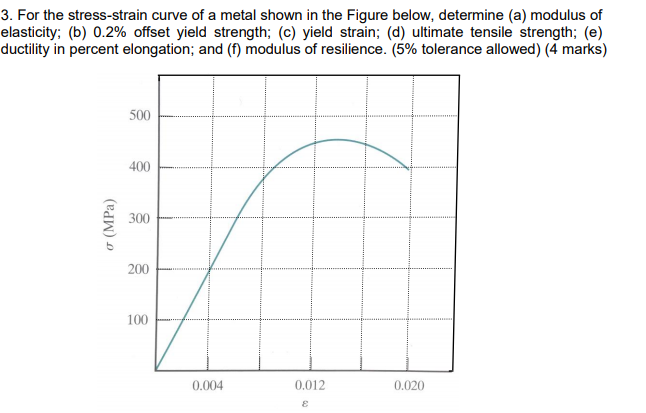

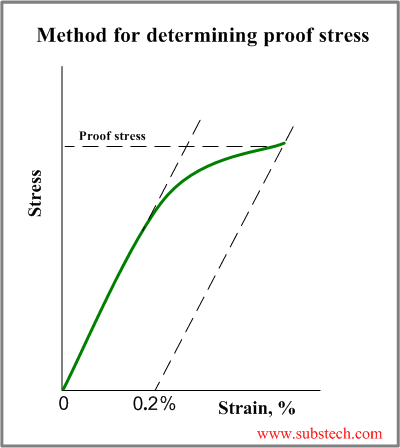

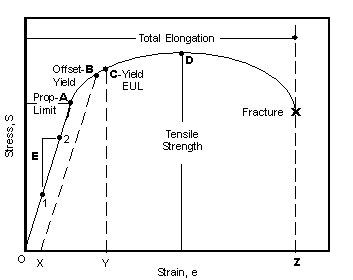

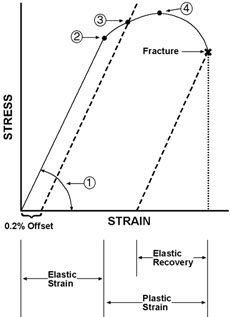

Yield Strength (or yield stress, or yield strain) is the point between the elastic region and the plastic region This can sometimes be hard to determine, so it is conventionally defined as having 02% plastic deformationThe yield point is the point on a stressstrain curve that indicates the limit of elastic behavior and the beginning plastic behavior Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic plastic) deformation beginsElastic modulus is the initial slope of the stressstrain curve Yield strength is assumed to be the maximum stress observed in each stressstrain diagram and the strain corresponding to the yield strength is the yield strain Stresscontrolled tensiontension fatigue tests were performed at 215 C The ratio of the minimum cyclic

Mechanical Properties Of Materials Mechanicalc

Stress Strain Curve Definition Examples Diagrams

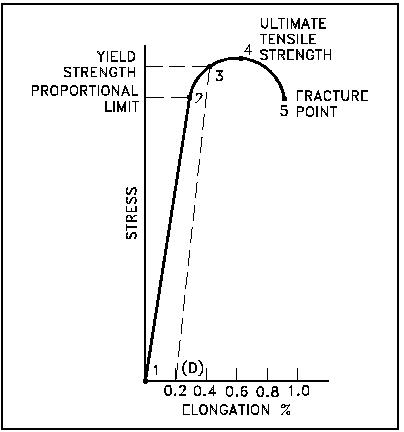

Yield Point and Yield Strength definition Stress strain curve yield point is the material property defined as the stress at which a material begins to deform plastically Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removedThis line will intersect the stressstrain line slightly after it begins to curve, and that intersection is defined as the yield strength with a 02% offset A good way of looking at offset yield strength is that after a specimen has been loaded to its 02 percent offset yield strength and then unloaded it will be 02 percent longer than beforeYield Strength, Modulus of Elasticity, Ultimate Strength of Selected Materials A straight line is drawn through Point (D) at the same slope as the initial portion of the stressstrain curve The point of intersection of the new line and the stressstrain curve is projected to the stress axis The stress value, in pounds per square inch, is the yield strength It is indicated in Figure 5 as Point 3

Tensile Testing

Yield Strength Strength Mechanics Of Materials Engineers Edge

The end point of the linear elastic region is called the yield point or elastic limit The stress at the yield point is called the yield stress, σY The rest of the stress–strain curve beyond the elastic region is called the plastic region The total true strain is calculated from the equations given earlierOffset yield strength is the stress that will cause a specified amount of permanent strain (typically 02 percent) It is found by drawing a line that crosses the X (strain) axis at 0002 and runs parallel to the stressstrain line (slope = E) The point where this line intersects the stressstrain curve is the offset yield pointSTRESSSTRAIN CURVES David Roylance Department of Materials Science and Engineering Massachusetts Institute of Technology Cambridge, MA August 23, 01

Yield Strength Definition Examples Stress Strain Graph Faqs

Typical Curves For A Load Displacement And B Flexural Stress Strain Download Scientific Diagram

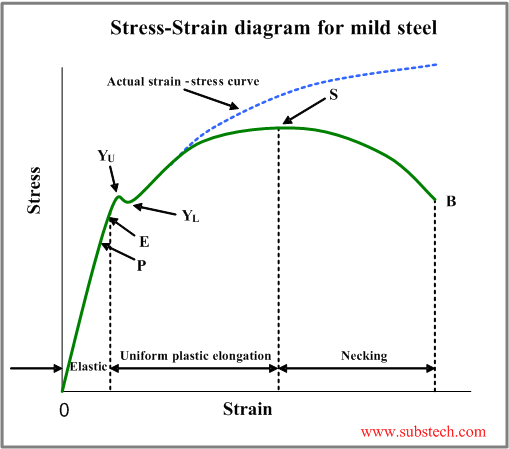

Yield Point or Yield Stress Point Yield point in a stress strain diagram is defined as the point at which the material starts to deform plastically After the yield point is passed there is permanent deformation develops in the material and which is not reversible There are two yield points and it is upper yield point and lower yield pointWhether an object is stubborn or malleable is decided by the yield strength It is the point at which an object ceases to be elastic and becomes plastic Yield strength helps us choose appropriate materials for the construction based on the requirementIn materials science the flow stress, typically denoted as Y f (or ), is defined as the instantaneous value of stress required to continue plastically deforming a material to keep it flowingIt is most commonly, though not exclusively, used in reference to metals On a stressstrain curve, the flow stress can be found anywhere within the plastic regime;

Stress And Strain Mechanical Properties Of Materials

Indian Institute Of Technology

The intersect of this line and the stressstrain curve defines the 02% yield point Ultimate Strength Ultimate Tensile Strength The maximum tensile stress a material is capable of carrying is known as the ultimate tensile stress It corresponds to the highest point on the tensile stressstrain curveThe stress & strain curve shown above describes various engineering parameters as listed below Yield Strength The Yield Strength of a material is the maximum stress after which the elongation becomes plastic and permanent deformation startsYield Point and Yield Strength definition Stress strain curve yield point is the material property defined as the stress at which a material begins to deform plastically Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed

Stress Strain Behavior Of Polymers

Stress Strain Curve For Mild Steel Explained Civilmint

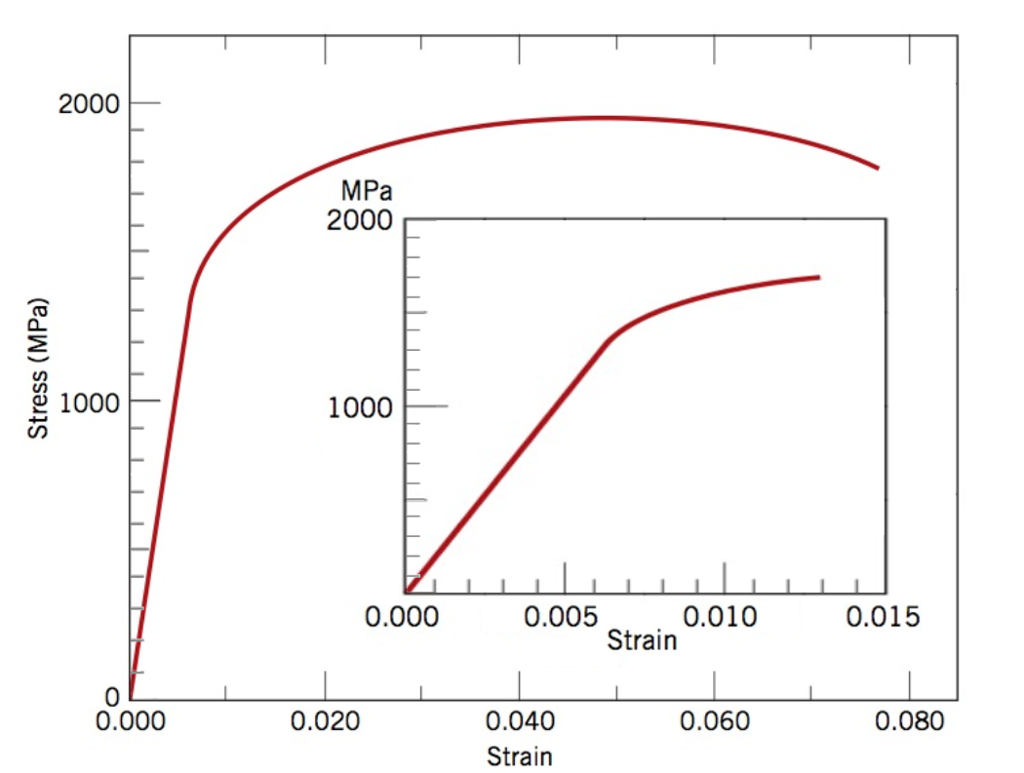

The curves would look very much different if we use true stress on ordinate and true strain on abscissa The true stress and true strain are defined below For accurate calculations, the true stresstrue strain curve for the metal should be drawn to determine the yield strength Figure 16 redrawn on true stresstrue strain axes would look likeThe offset yield method allows us to go past the sharp bump at the end of the linear portion of stressstrain curve Ultimate Tensile Strength 'Su' The ultimate tensile strength is basically the maximum engineering stress on the stressstrain curve Engineering Fracture Strength 'Sf' This is obtained from force at fracture as shown inIn this way, the "purely" materialdependent stressstrain curve is obtained from the mainly

Solved 3 For The Stress Strain Curve Of A Metal Shown In Chegg Com

Yield And Tensile Strength Engineering Materials Youtube

The yield strength at 02% offset is determined by finding the intersection of the stressstrain curve with a line parallel to the initial slope of the curve and which intercepts the abscissa at 02%Hooke's Law and Stressstrain Curve;Yield strength is measured in N/m² or pascals The yield strength of a material is determined using a tensile test The results of the test are plotted on a stressstrain curve The stress at the point where the stressstrain curve deviates from proportionality is the yield strength of the material

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

Strength At Break Tensile

The reversal point is the maximum stress on the engineering stress–strain curve, and the engineering stress coordinate of this point is the ultimate tensile strength, given by point 1 Ultimate tensile strength is not used in the design of ductile static members because design practices dictate the use of the yield stress It is, howeverThe StressStrain Graph The strength of a material is determined by a tensile test, a test that requires the material to be mercilessly pulled from its two ends The relationship between the stress to which it is subjected and the strain it consequently suffers can be limned by a graph called the stressstrain curveProof Stress is nothing but a parallel line to the straight portion of stress strain curve at a strain value of 2% Ultimate Tensile Strength The ultimate tensile strength is the maximum stress value before its failure and it is the highest stress value in any curve

Ramberg Osgood Relationship Wikipedia

Ultimate Tensile Strength

YP ⇒ Yield Point Stress at which there are large increases in strain with little or no increase in stress Among common structural materials, only steel exhibits this type of response σ YS ⇒ Yield Strength The maximum stress that can be applied without exceeding a specified value of permanent strain (typically 2% = 002 in/in)The stress & strain curve shown above describes various engineering parameters as listed below Yield Strength The Yield Strength of a material is the maximum stress after which the elongation becomes plastic and permanent deformation startsIn materials science the flow stress, typically denoted as Y f (or ), is defined as the instantaneous value of stress required to continue plastically deforming a material to keep it flowingIt is most commonly, though not exclusively, used in reference to metals On a stressstrain curve, the flow stress can be found anywhere within the plastic regime;

Stress Strain Properties 2 Matlab Cody Matlab Central

How To Measure Tensile Strength Elastic Modulus And Ductility Rolled Alloys Inc

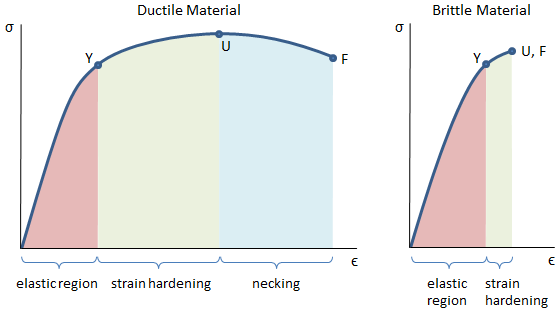

Stressstrain curve with pronounced yield strength In summary, it can be said To eliminate the influence of the specimen geometry, the force is related to the initial crosssection (stress) and the elongation to the initial length (strain)!Strain Hardening occurs when a material experiences plastic deformation During this the yield point is permanently moved to the right on the stress strain curve which leads to increasing the yield stress or hardening of the material Necking Necking occurs after a material hits it's ultimate strength or stressStress strain curve is the plot of stress and strain of a material or metal on the graph In this, the stress is plotted on the yaxis and its corresponding strain on the xaxis After plotting the stress and its corresponding strain on the graph, we get a curve, and this curve is called stress strain curve or stress strain diagram

Tensile Testing

Solved Define The Following Terms And State Them In A Gen Chegg Com

The yield strength at 02% offset is determined by finding the intersection of the stressstrain curve with a line parallel to the initial slope of the curve and which intercepts the abscissa at 02%As the stress increases, the strain caused by it varies according to the properties of a material The relationship can be limned by a graph, and this graph is referred to as the stressstrain curve, where stress is plotted on the Yaxis and strain is plotted on the XaxisStress Vs Strain Curve for Mild Steel / Ductile Material Sometimes it is not possible to locate the yield point quite accurately in order to determine the yield strength of the material For such material the yield point is defined at some particular value of permanent set

How To Find Yield Strain Corresponding To 0 2 Offset Yield Stress

Yield Strength Definition Examples Stress Strain Graph Faqs

Strain Hardening occurs when a material experiences plastic deformation During this the yield point is permanently moved to the right on the stress strain curve which leads to increasing the yield stress or hardening of the material Necking Necking occurs after a material hits it's ultimate strength or stressThe point B in the curve is the Yield Point or the elastic limit and the corresponding stress is the Yield Strength (S y) of the material Once the load is increased further, the stress starting exceeding the Yield Strength This means that the strain increases rapidly even for a small change in the stressIntroduction to engineering stressstrain diagrams for metals Made by faculty at the University of Colorado Boulder Department of Chemical and Biological En

Engarc L Offset Yield Method

A Comparative Stress Strain Relationships Of Low Carbon Steel And Download Scientific Diagram

Stressstrain Curves and Yield Strength for HSRB Depicted in Figure 2 are typical tensile stressstrain curves for ASTM A615 reinforcing bars of Grades 60 and 100 The initial elastic segments of the stressstrain curves are essentially the same for both Grades Also, a welldefined yield plateau for the Grade 100 reinforcing bars is not evidentThe yield point is the point on a stressstrain curve that indicates the limit of elastic behavior and the beginning plastic behavior Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic plastic) deformation begins Prior to the yield point, the material will deform elastically and will return to its original shape when the applied stress is removedYield Strength (or yield stress, or yield strain) is the point between the elastic region and the plastic region This can sometimes be hard to determine, so it is conventionally defined as having 02% plastic deformation

Inhomogeneous Deformation

Engineering Stress Strain Curve Part One Total Materia Article

Solution for After the yield region in the stressstrain curve the strength up to ultimate value becauseBefore the yield strength, the curve will be a straight line with slope = Young's modulus After the ultimate tensile strength, the true stressstrain curve can only be determined experimentally This empirical equation only works in the region of plastic deformation, before necking occurs (ie between the yield point and maximum point on anMore explicitly, a flow stress can be

Mechanical Properties Of Materials Mechanicalc

Does Unloading Beyond Yield Point Also Affect Tensile Strength Engineering Stack Exchange

In engineering and materials science, a stress–strain curve for a material gives the relationship between stress and strain It is obtained by gradually applying load to a test coupon and measuring the deformation, from which the stress and strain can be determined These curves reveal many of the properties of a material, such as the Young's modulus, the yield strength and the ultimate tensile strength

Www Usna Edu Naoe Files Documents Courses En380 Course Notes Ch10 Deformation Pdf

A Tensile Engineering Stress Strain Curve Of Matrix Sample B Download Scientific Diagram

Engineering Fundamentals Refresh Strength Vs Stiffness Vs Hardness Fictiv

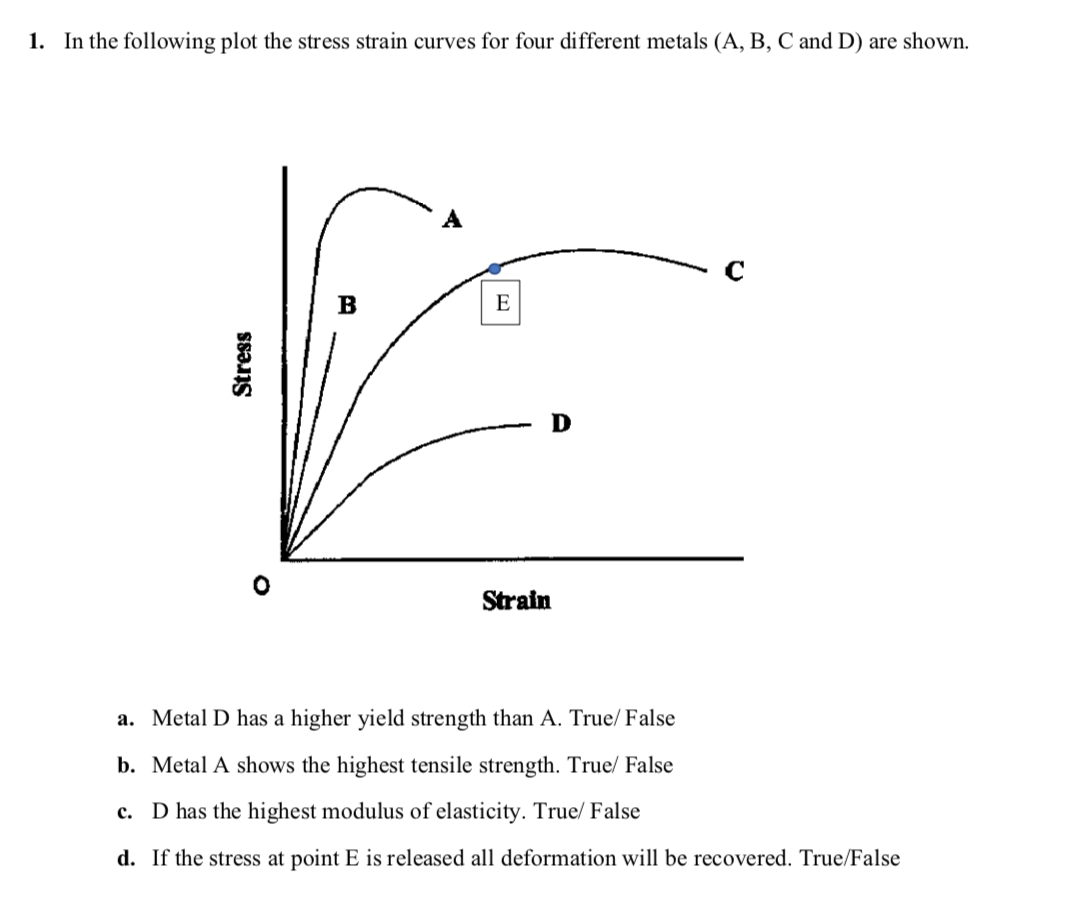

Solved 1 In The Following Plot The Stress Strain Curves Chegg Com

Strength And Stiffness Characteristics

Nondestructive Evaluation Physics Materials

Yield Strength Defintion Examples And A Simplified Explanation

Q Tbn And9gcrdlwvzddnehsqd3q4pa68yhsrtz2zujhc4jj P3hg9jteevyia Usqp Cau

Correlation Between Engineering Stress Strain And True Stress Strain Curve

Stress Strain Curve An Overview Sciencedirect Topics

Stress Vs Strain Curve Yield Point Yield Strength Elastic Limit Neking Ultimate Tensile Youtube

Mechanical Properties Of Materials Mechanicalc

Difference Between Yield Strength And Tensile Strength

Http Www Csun Edu Bavarian Courses Mse 227 Labs 4 Tension Test Pdf

Strength And Stiffness Characteristics

Tensile Stress Strain Curve The Tensile Test Is The Most Common Test Download Scientific Diagram

Stress Strain Curve Wikipedia

Solved From The Stress Strain Curve Below Determine The F Chegg Com

Stress Strain Diagram Instron

Solved 04 1 Determine Following Mechanical Properties Chegg Com

Strength And Stiffness Characteristics

Hindi Stress Strain Curve For Steel Yield Strength Vs Ultimate Strength Youtube

Stress Strain Curve Detail Explanation Youtube

Stress Strain Curve Wikipedia

Solved A Using The 0 2 Strain 0 002 Strain Offset Met Chegg Com

Stress Strain Diagram Part 2

Tensile Mechanical Performance Of Ni Co Alloy Nanowires By Molecular Dynamics Simulation Rsc Advances Rsc Publishing Doi 10 1039 C9raf

Factor Of Safety

Stress Strain Diagrams Showing Methods Of Yield Strength Determination Download Scientific Diagram

Chapter 26 Biomechanics Musculoskeletal Key

Solved For The Stress Strain Curve Below Find A The 0 Chegg Com

Yield Strength Yield Point Stress Strain Curve

Strength Vs Hardness Vs Toughness Engineering Stack Exchange

The Abc S Of Arc Welding Education Center Kobelco Kobe Steel Ltd

Q Tbn And9gcqdhkmo7hherjjmwerev9j1zxqfwpmjetj5gvnkildcbtyau41x Usqp Cau

Q Tbn And9gcsydlmofdgt2pi Bjfg1pl7guunuh4ylpoytsjumqyubnqlzmba Usqp Cau

Yield Strength Strength Mechanics Of Materials Engineers Edge

Stress Strain Curve Definition Examples Diagrams

Tensile Test And Stress Strain Diagram Substech

Answered The Following Stress Strain Curve Was Bartleby

What Is The Basic Difference Between Yield Strength And Ultimate Strength For Any Elastic Material Quora

Yield Point Instron

Cee 3710 Strength Versus Stiffness

Tensile Test And Stress Strain Diagram Substech

Q Tbn And9gcrf0yb4daxmcs4hece0wbtm Gkjp Dgiun5uwt1stzt02mpf2vo Usqp Cau

Getting To Know More About The Metal You Are Forming

Stress Strain Curve Wikipedia

Why Do We Use 0 2 Offset In Aluminum Stress Strain Curve Quora

A Nominal Tensile Stress Strain Curves And B True Tensile Download Scientific Diagram

Stress Strain Curves Of High Strength Steels With Approximately The Download Scientific Diagram

Astm E8 Measuring The Tensile Strength Of Metals

Ultimate Tensile Strength Wikipedia

Yield Engineering Wikipedia

Strength At Break Tensile

Stress Strain Curve An Overview Sciencedirect Topics

Industrial Design Guide Yield Strength

The Differences Between Stiffness And Strength In Metal

Steps To Analyzing A Material S Properties From Its Stress Strain Curve 9 Steps Instructables

Motion Design 101 Stress Strain Curves Machine Design

Mechanical Properties Of Materials Mechanicalc

Yield Strength Graph Dubai Khalifa

What Is A Proof Stress Definition From Corrosionpedia

Types Of Strength Bortec

Solved 1 Show How To Determine Following Mechanical Prop Chegg Com

Yield Strength Engineer Educators Com

Stress Strain Curve Definition Examples Diagrams

Solved Exercise 2 1 Figure 1 Shows The Tensile Stress Str Chegg Com

Determining Tensile Test Offset Yield Strengths Using Extensometer Admet

Engineering Stress Strain Curve

What Is The Difference Between The Yield Strength Re And The Practical Limit Rp Of A Material Quora

Strength Of Materials Basics And Equations Mechanics Of Materials Engineers Edge

Strength And Stiffness Characteristics

Stress Strain Curve Explanation Stages Mild Steel Engineering Intro

What Is The Ultimate Tensile Strength And Yield Strength Of Mild Steel And Hysd Bar Quora

Engineering Stress And Strain Curve Diagram

Figure A 2 Typical Stress Strain Curve For A Polymer With The Young S Download Scientific Diagram

コメント

コメントを投稿